Steel panels are designed and adopted to bear and disperse the reaction force given from the fender body to the berthing vessel and reduce the surface pressure. Hence, the design of the steel panels should be comply to the actual berthing condition. The bearing strength of the steel panel is related to many factors such as vessel type, berthing method, performance of the rubber fender, tidal range etc. However, there are some common requirements that should be considered on the design and production of the steel panels:

a. the steel panel should be resistant to deflection and shearing force.

b. the steel panel should be resistant to locally impact.

c. no deformation during compression process.

d. friendly to environment, be resistant to corrosion.

The structure type of the steel panel

There are two structure types of the steel panel, opening type and closing type. Generally, opening type steel panel consists of facing panel, longitudinal girder and cross girder; closing type steel panel is composed of facing panel, back panel and girder.

How to calculate the size of the steel panel

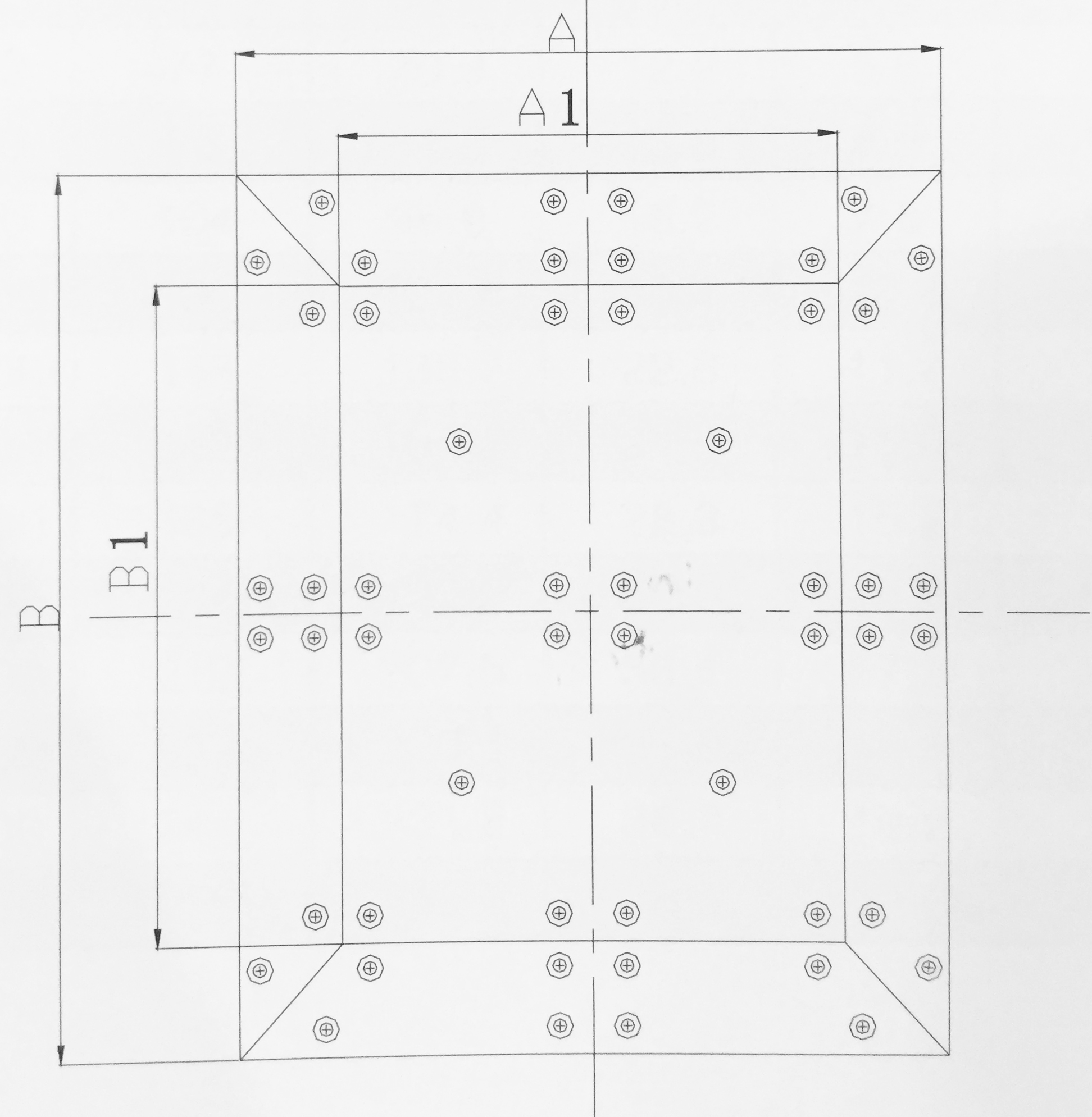

The design size of the steel panel should meet the following formular:

P = ∑R/(A1*B1)≤Py

Where,

P = Surface Pressure

∑R = Sum of the max reaction force of each fender body in one system

A1 = Width of the steel panel

B1 = Length of the steel panel

Py = Allowable surface pressure of the vessel hull

So that it will be easy to calculate the size of steel panel if you know the allowable surface pressure.

Please refer to the following tale ( PIANC 2002:Table 4.4.1 ) if the allowable surface pressure is not available.

[ws_table id=”8″]

How to calculate the strength of the steel panel

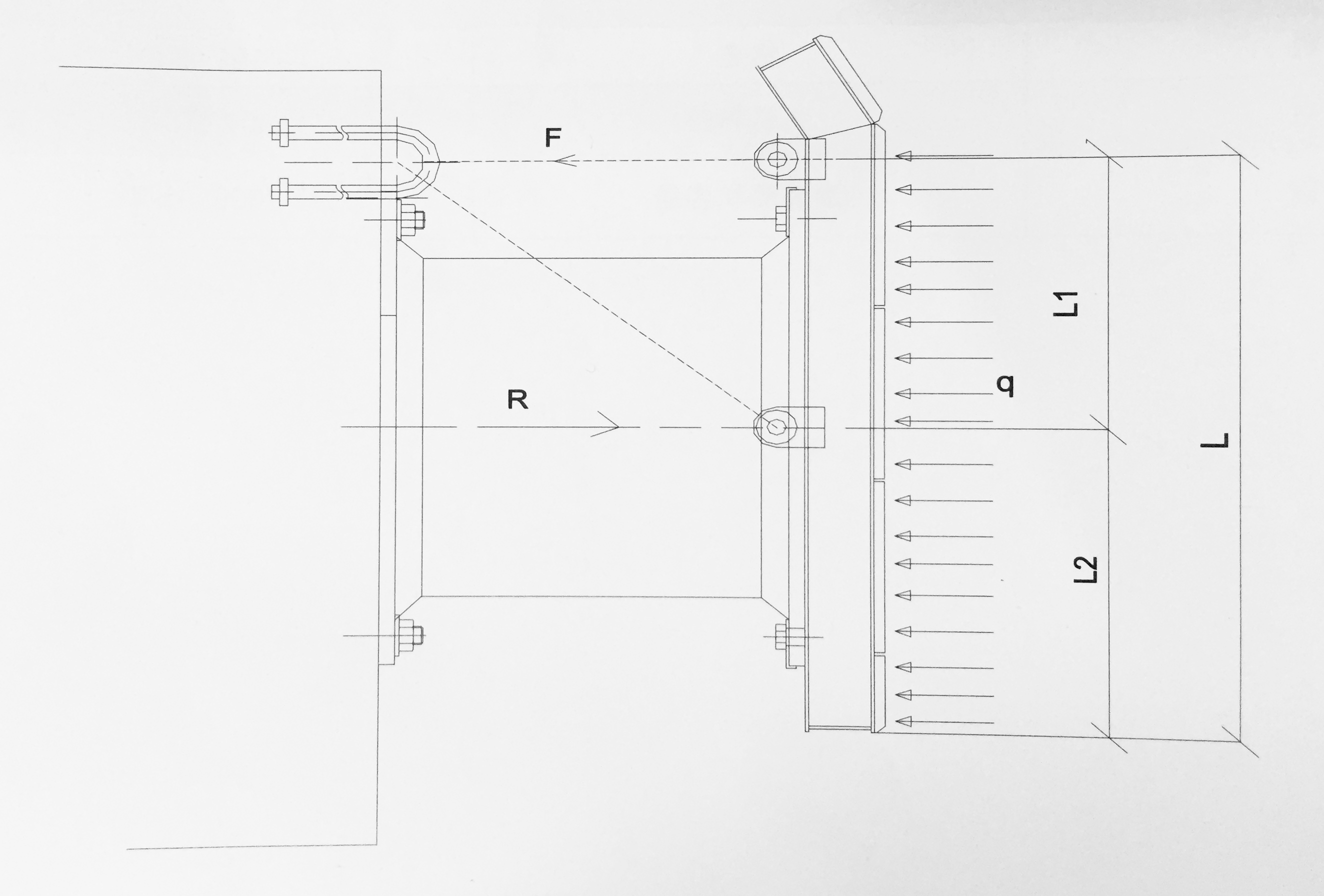

a. uniformly distributed load

R = F + q.L

F = (2R/L)*(0.5L-L1)

q = (2R*L1)/L2

Mmax = (R*L1*L22)/L2 = (R*L13)/L2 + F*L1

Where,

R = Reaction force

q = Uniformly distributed load of the steel panel

F = Balance force

L = Effective contact length of the steel panel

Mmax = Max torque

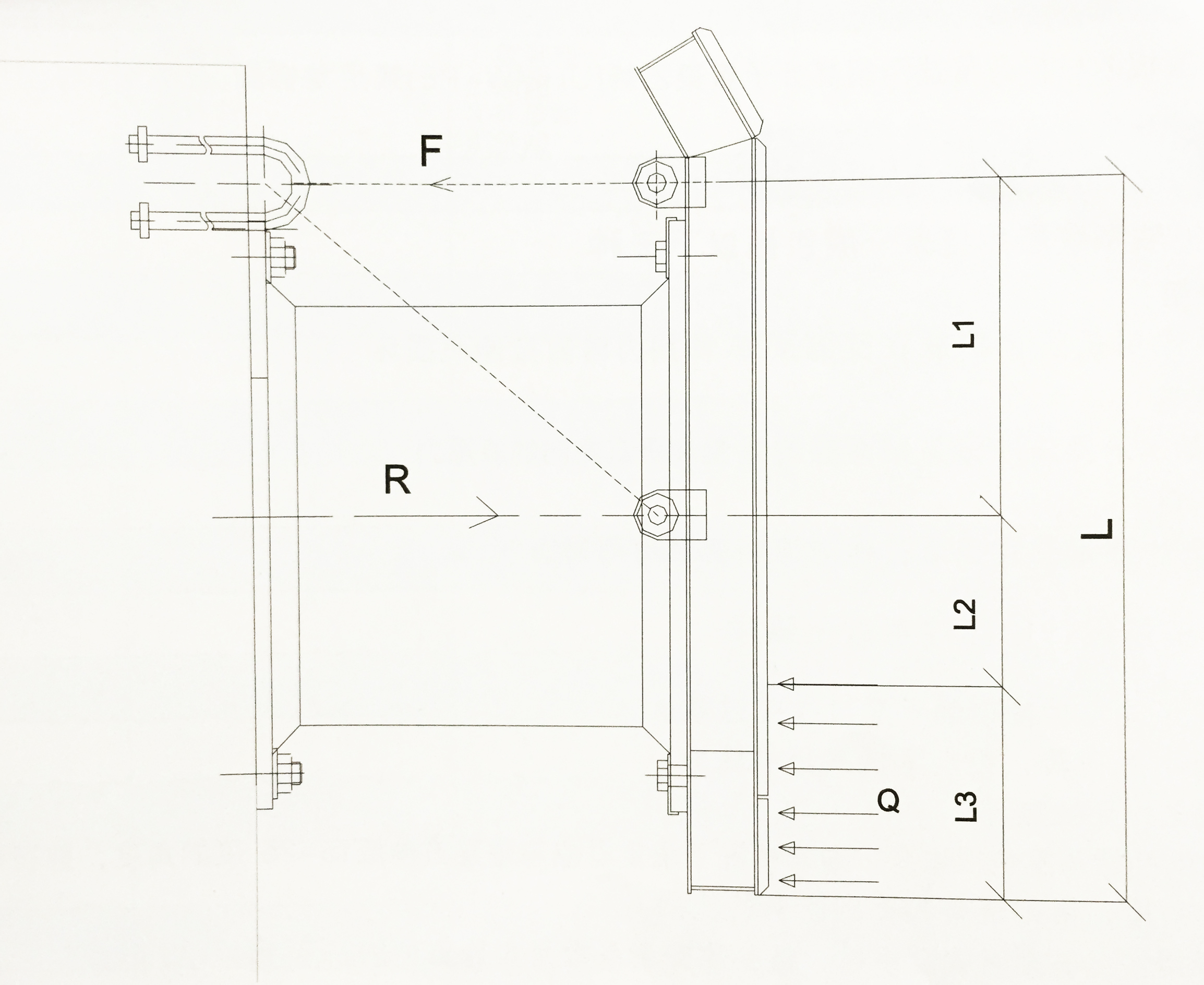

b. non-uniformly distributed load

R = F + Q

Q = (R*L1)/(L-0.5L3)

F = R*(L2+0.5L3)/(L-0.5L3)

Mmax = Q*(L2+0.5L3) = F*L1

Where,

R = Reaction force

Q = Contact load

F = Balance force

L = Effective contact length of the steel panel

Mmax = Max torque

Contact Us

Feel free to contact us if you have any comments or inquires and one of our skilled staff representatives will contact you within the next business day.

Contact Details

- No.8 Jier Road, Jiaozhou Jiaobei Industrial Zone, Qingdao, China

- +86 186 602 306 15

- jierfender@gmail.com

- Contact Form